1. Overview

1.1 Overview

& Rigid clear PVC extrusion molding is one of the important molding methods for rubber and plastic molding processing. Most thermoplastics and rubbers can be processed in this way.

1. The characteristics of rigid clear PVC extrusion molding

& Compared with other molding methods, rigid clear PVC extrusion molding has the following characteristics:

& 1) The production process is continuous, so its products are continuous; that is, continuous production

& 2) High production efficiency, one φ200 extruder 700kg/hour, Germany φ500 extruder 20t/hour;

& 3) A wide range of applications, capable of producing pipes, bars, plates, films, monofilaments, wires, cables, profiles, and hollow products, etc.;

& 4) Low investment and quick results.

& 5) Simple structure and easy operation.

& Products produced with rigid clear PVC extrusion molding are widely used in people's lives and industrial sectors such as agriculture, construction, petrochemicals, machinery manufacturing, and national defense.

& The rigid clear PVC extrusion molding is carried out on the extruder, which is one of the important machines for rubber and plastic molding processing machinery.

2. The composition of the extruder

& The extrusion process is carried out as follows: the plastic is heated to make it in a viscous state, and under pressure, it is passed through a die with a certain shape to become a continuum with a cross-section similar to the shape of the die, and then passed Cooling makes the plastic with a certain geometric shape and size change from a viscous fluid state to a highly elastic state, and finally cooling and shaping it into a glass state to obtain the desired product. (Glass state-viscous flow state-high elastic state-glass state)

& In order to carry out the molding process, an extruder is generally composed of the main engine, auxiliary machinery, control system and other parts:

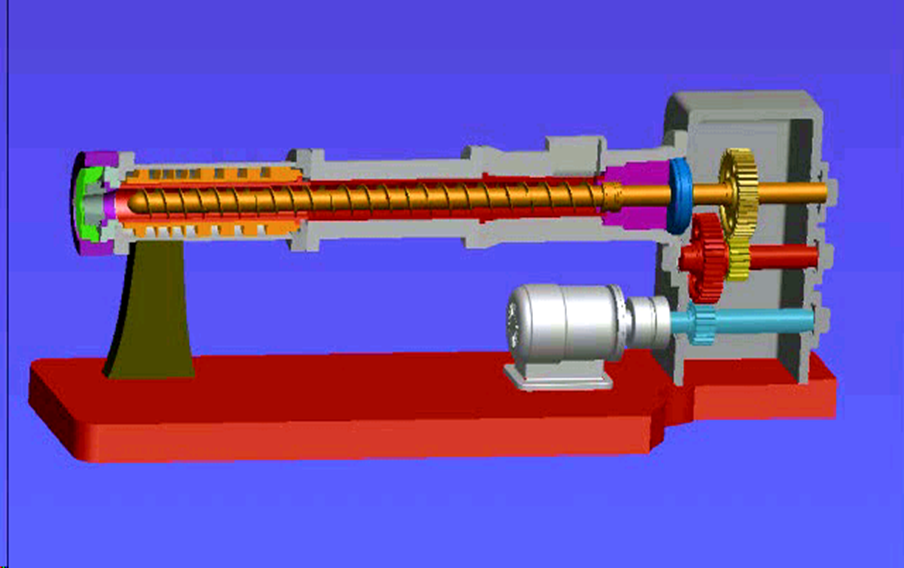

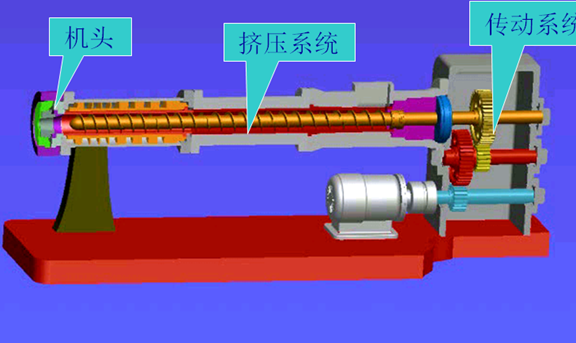

1) Host

& Extrusion system: mainly composed of barrel and screw. The plastic is plasticized into a uniform melt through the extrusion system, and under the pressure established in this process, the screw is continuously extruded with constant pressure and constant temperature.

& Transmission system: its role is to provide the required torque and speed to the screw.

& Heating and cooling system: Its function is to heat and cool the barrel (or screw) to ensure that the molding process is completed within the temperature range required by the process.

2) Auxiliary machine

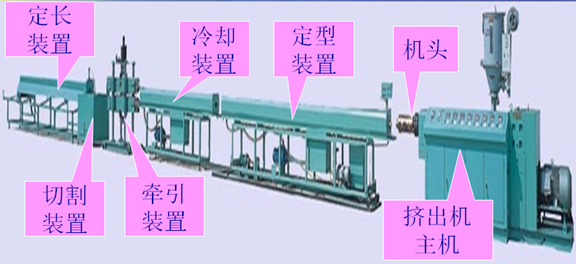

& Head: The molten plastic obtains a certain geometric cross-section and size through it.

& Shaping device: its function is to stabilize the established shape of the plastic extruded from the die. And it is refined to obtain a more accurate cross-sectional shape, size and bright surface. Usually use cooling and pressurizing methods to achieve this goal.

& Cooling device: The plastic from the shaping device is fully cooled here to obtain the final shape and size.

& Traction device: its function is to haul products evenly. And control the cross-sectional size of the product, so that the extrusion process can be carried out stably.

& Cutting device: cut the continuously extruded product into a certain length or width.

& Winding device: Winding soft products (film, hose, monofilament, etc.) into rolls.

Plastic pipe unit

& 3) Control system (detection and control)

& The control system of the extruder: it is composed of various electrical appliances, instruments and actuators.

& According to the level of automation, the main engine of the extruder, the driving motor of the auxiliary engine, the driving oil pump, the oil (cylinder) cylinder and other various actuators can be operated according to the required power, speed and trajectory, as well as detection Control the temperature, pressure and flow of the main and auxiliary machines, and finally realize the automatic control of the entire extrusion unit and the control of product quality.

& Generally, the extruder composed of the above parts is called the extruder unit.

& To be continued...